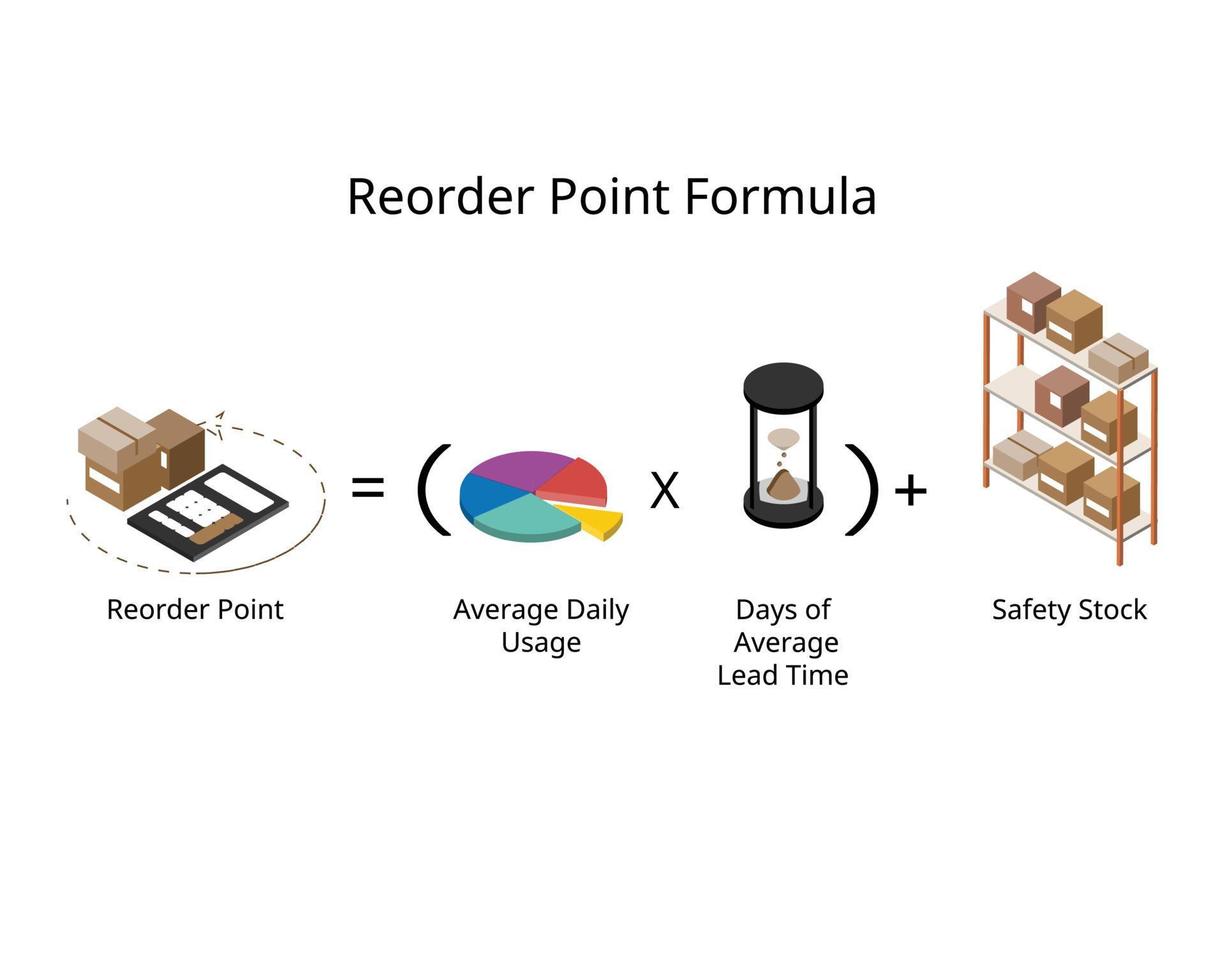

Find out when to order more inventory without running out by calculating your reorder point (ROP). ShipBob’s platform doesn’t just help with inventory control and forecasting, but generates powerful analytical reports covering all areas of your business. You can get inside the numbers and find new ways to improve supply chain efficiency. It’s important to keep adequate safety stock on-hand as demand can increase suddenly or problems with a supplier can prevent you from restocking inventory as quickly as you expected.

Example 1 – reorder level without safety stock

So there you have it, a complete guide to mastering the art and science of how to deduct mortgage points on your tax returns. Armed with this knowledge, you’re well-prepared to navigate the labyrinth of stock administration, making informed decisions that positively impact your bottom line. As you venture forth, remember that Bezos stands ready to be your valued ally, offering a suite of tools designed to make your journey not just manageable but truly optimised. Public holidays, weekends, and even specific times of the month can significantly impact both demand and supply chain operations. In the realm of merchandise management, the term “reorder level” might sound technical, but its essence is straightforward.

Products

Setting a reorder point can help you reorder in time to avoid this availability gap. In this retailer’s guide to reorder points, you’ll learn everything you need to know to set effective reorder points and much more. Sourcetable is designed to meet the needs of anyone looking to deepen their understanding of mathematical concepts or enhance their professional workflow. Its ability to explain complex calculations in simple terms makes it an excellent resource for students and professionals alike. Whether you’re preparing for an exam or managing a business, Sourcetable provides the tools you need to succeed.

- Effective management of restock levels is vital for successful inventory management, balancing product availability with minimising excess inventory costs.

- By implementing these strategies, businesses can create a dynamic and responsive system for managing reorder levels, contributing to overall efficiency and customer satisfaction.

- This ongoing evaluation ensures that your reorder levels remain effective and aligned with your business needs.

- For instance, if the backlog or lost-sale cost is much higher than the holding cost, the retailer should set a higher reorder point to avoid stockout, and vice versa.

Ask Any Financial Question

Assess Safety Stock Needs based on factors such as demand variability, supply chain reliability, and the cost of stock-outs. This can involve statistical analysis, but a simple method is using a percentage of lead time demand. For example, with a 20% safety stock, the calculation would be 1,400 units multiplied by 20%, resulting in 280 units of safety stock.

In this section, we’ll delve deeper into these factors, offering you a roadmap to navigate the complexities. Maximum Daily Usage considers the highest amount of an item needed in a single day, preparing businesses for peak demands without overstocking during normal periods. Some accountants do not differentiate between the ordering level and the minimum stock level, but others draw a distinction between the two. In other words, the reorder stock level is the level of inventory at which a new purchase order should be placed. Generally, it is best practice to review reorder points every three to six months.

A reorder point (ROP) is the level at which inventory needs to be replenished so it doesn’t drop below a certain threshold where it is at risk of going out of stock. Thankfully, one way to get this right is to use the Reorder Point Formula (FOP) to calculate your reorder level, eliminating the need for guesswork and using your gut instinct to make decisions. It’s not uncommon for the number of SKUs a business sells to grow as the business does. When this happens, it gets much more difficult to manage inventory, and we can end up forgetting about those products lying on the shelf that nobody has bought.

Use POS data and empirical evidence to determine when to reevaluate your ROP. With the right tools, there’s no need to manually calculate reorder points. A grocery store, for example, would likely have higher reorder points for quick-selling produce than a furniture store would for slow-selling mattresses.

This team of experts helps Finance Strategists maintain the highest level of accuracy and professionalism possible. At Finance Strategists, we partner with financial experts to ensure the accuracy of our financial content. The articles and research support materials available on this site are educational and are not intended to be investment or tax advice. All such information is provided solely for convenience purposes only and all users thereof should be guided accordingly. For information pertaining to the registration status of 11 Financial, please contact the state securities regulators for those states in which 11 Financial maintains a registration filing.

Therefore, it’s best to think of your reorder point on an individual item level. Calculating ROP for each product can be time-consuming and challenging, especially if your inventory is patched together from several suppliers or you sell lots of products. ShipBob’s cutting-edge inventory management software and analytics tools make it easier than ever. So now you know the reorder point formula, but you might be wondering – what is demand during lead time? In this section we break down ROP and tell you exactly how to calculate it. The Reorder Point Formula assumes that demand is constant throughout the year, and as such, won’t be accurate if demand is not consistent.

We also partner with some of the world’s best fulfilment centres, warehouses, and locker networks. Say goodbye to stockouts and overstocking and hello to a lean, efficient inventory. Alright, enough theory – let’s roll up our sleeves and dive into the formula that makes reorder levels tick. Safety stock which ABC Ltd. has decided to hold equals 2,500 units (500 units of daily usage multiplied by 5 days).

Therefore, you should only use the FOP for products that have similar levels of demand throughout the year. Using data to reorder inventory rather than your gut feeling has knock-on positive effects. You’ll naturally need a good understanding of your data to work out a reorder point calculation, and you can use this data in other ways. This includes identifying seasonal trends, forecasting demand, and a deeper understanding of inventory health. From the above formula it can be easily deduced that an order for replenishment of materials be made when the level of inventory is just adequate to meet the needs of production during lead-time. Using data to reorder inventory rather than your gut feeling has knock on positive effects.